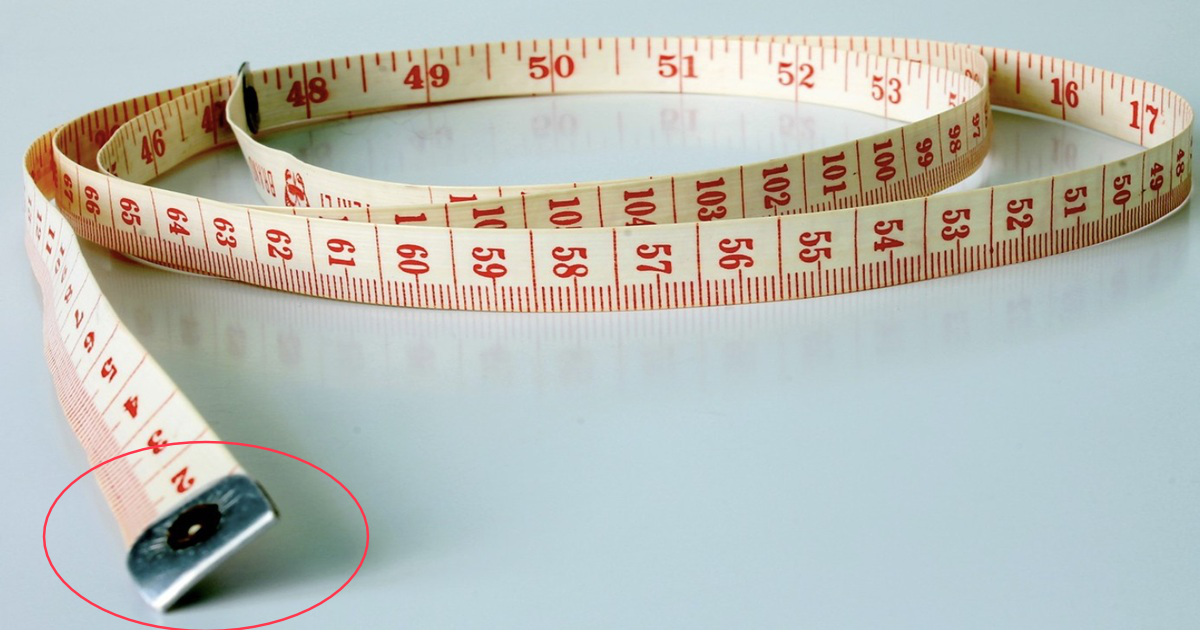

Measuring tapes are a staple in toolboxes around the world, used by professionals and DIY enthusiasts alike. Despite their ubiquity, many people misunderstand one of their key features: the loose tip. This seemingly faulty component often leads users to believe their tape is broken or defective. However, this design is intentional and serves a critical function. Understanding the purpose behind this feature can enhance the accuracy of measurements and improve the overall user experience.

The Common Misconception About the Loose Tip

When people first notice the loose tip of a measuring tape, they often assume it is a manufacturing defect. The tip, which appears to wobble or move slightly, can be mistaken for a sign of wear and tear. This misconception is widespread, as most users are not aware of the engineering behind this design. As a result, they may attempt to fix the ‘problem’ themselves, potentially compromising the tape’s functionality.

Understanding the Design of a Measuring Tape

The design of a measuring tape is a marvel of engineering, combining simplicity with functionality. The tape itself is made of a flexible metal strip that can be easily extended and retracted. The markings on the tape are precise, allowing for accurate measurements. The loose tip, often made of metal, is attached to the end of the tape. This tip is designed to move slightly, a feature that is crucial for ensuring accurate measurements whether the tape is used to measure inside or outside dimensions.

The Purpose Behind the Loose Tip

The loose tip of a measuring tape is designed to account for the thickness of the tip itself. When measuring outside dimensions, such as the length of a table, the tip is pushed against the edge of the object, and the movement compensates for the thickness of the tip. Conversely, when measuring inside dimensions, such as the width of a window frame, the tip is pulled against the object, and the movement again compensates for the tip’s thickness. This ensures that the measurement is accurate in both scenarios.

The Benefits of the Loose Tip Feature

Ensures Consistent Accuracy Across Measurement Types

The loose tip feature compensates for the thickness of the metal hook, providing precise readings whether measuring from the inside (e.g., between two walls) or the outside (e.g., along a board).

Eliminates the need for users to manually adjust or calculate differences, reducing the chance of human error in measurements.

Enhances Versatility for Diverse Tasks

Makes the measuring tape adaptable to various applications, such as carpentry, sewing, or home improvement projects, regardless of whether the measurement starts at the edge or includes the hook.

Suitable for both professional and DIY use, broadening its utility across skill levels and industries.

Saves Time and Boosts Efficiency

By automatically accounting for the hook’s movement, users can quickly take measurements without pausing to double-check or adjust for inaccuracies.

Speeds up workflows, especially in repetitive tasks, as the feature ensures reliability with minimal effort.

Reduces Frustration and Builds Confidence

Users can trust the measurements they get without second-guessing, leading to smoother project execution and fewer mistakes.

Simplifies the measuring process, making it less stressful for beginners or those unfamiliar with advanced tools.